Please Choose Your Language

Views: 222 Author: Carie Publish Time: 2025-02-24 Origin: Site

Content Menu

● Introduction to Surface Treatment Additives

>> Silicones as Surface Modifiers

>> Silica as Surface Modifiers

>> Surfactants as Surface Modifiers

>> Organic Corrosion Inhibitors

>> Inorganic Corrosion Inhibitors

● Metal Surface Treatment Techniques

● Chemical Raw Materials in Surface Treatment

>> High Polymer Surface Active Agents

● FAQ

>> 1. What are the primary types of flow and leveling agents used in coatings?

>> 2. How do silicones enhance coatings?

>> 3. What is the role of surfactants in surface modification?

>> 4. What are the benefits of road surface treatment?

>> 5. How do high polymer surface active agents regulate interfacial tension?

● Citation

Surface treatment additives play a crucial role in enhancing the properties and performance of various materials, including coatings, metals, and other surfaces. These additives are designed to improve aspects such as durability, appearance, and functionality by modifying the surface characteristics. In this article, we will delve into the different types of surface treatment additives, their applications, and how they are used in various industries.

Surface treatment additives are chemical raw materials that are incorporated into coatings or applied directly to surfaces to achieve specific effects. They can be categorized based on their functions, such as flow and leveling agents, surface modifiers, and corrosion inhibitors. Each type of additive serves a unique purpose, such as improving substrate wetting, reducing surface tension, or enhancing resistance to environmental factors.

Flow and leveling agents are commonly used in coatings to ensure smooth, even finishes. Polydimethylsiloxane (PDMS) additives are widely used for this purpose due to their ability to reduce surface tension and improve flow characteristics. PDMS additives come in various forms, including pure PDMS, organically modified PDMS, and polyether-modified PDMS[1].

These additives can be tailored to address specific paint film defects by adjusting their molecular weight. For instance, low molecular weight PDMS improves substrate wetting and flow, while higher molecular weight versions enhance surface slip and reduce air entrapment[1].

For applications where silicone-based additives are not suitable, acrylic flow and leveling agents offer a silicone-free alternative. These additives provide similar benefits without the potential incompatibility issues associated with high molecular weight PDMS[1].

Surface modifying agents are used to alter the surface properties of materials, such as wettability, adhesion, and durability. Common types include silicones, silica, and surfactants.

Silicones are versatile additives that enhance the application, adherence, and durability of coatings. They improve wetting, defoaming, and release characteristics, making them ideal for various industries, including automotive and aerospace[5].

Silica is used to achieve matte finishes in coatings. However, its effectiveness is limited in high-solid or solvent-free coatings due to the lack of film shrinkage during drying[9].

Surfactants are primarily known for improving pigment dispersion but also serve as effective additives for modifying surface properties. They enhance the interaction between coatings and substrates, improving adhesion and durability[9].

Corrosion inhibitors are critical additives used to protect metal surfaces from degradation caused by environmental factors. These additives form a protective layer on the metal surface, preventing moisture and corrosive substances from coming into contact with the metal.

Organic corrosion inhibitors are widely used due to their effectiveness and environmental compatibility. They work by adsorbing onto the metal surface, creating a barrier that prevents corrosion.

Inorganic corrosion inhibitors, such as chromates and phosphates, are also effective but may have environmental concerns. They are often used in applications where high corrosion resistance is required.

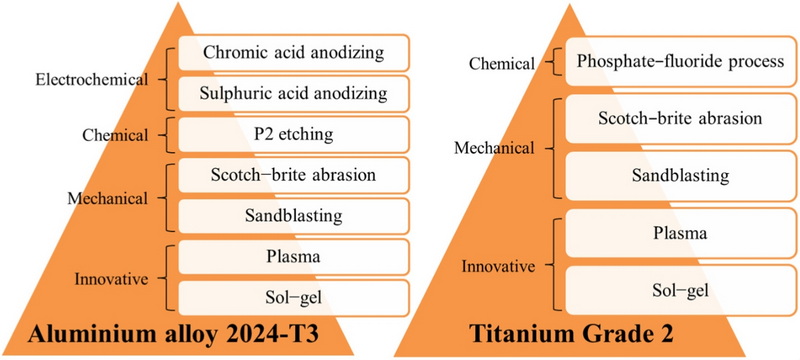

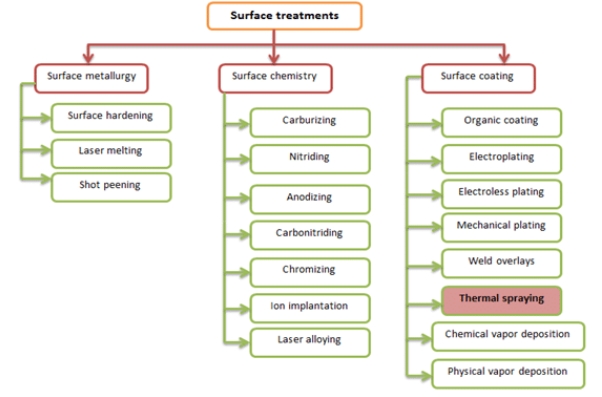

In addition to additives, various surface treatment techniques are used to enhance metal surfaces. These include:

- Polishing: Creates a smooth, shiny surface by rubbing or chemical treatment.

- Sandblasting: Smooths rough surfaces by propelling abrasive materials.

- Wire Drawing: Produces a satin finish with decorative lines.

- Anodic Oxidation: Forms an oxide film on metals through electrochemical processes.

- PVD (Physical Vapor Deposition): Deposits thin films on surfaces using vacuum methods.

- Electroplating: Deposits a thin layer of material onto a conductive surface.

- Painting: Applies coatings for aesthetic and protective purposes.

- Etching: Removes surface layers using chemical reactions.

- Laser Engraving: Creates designs or patterns using laser beams.

- Screen Printing: Applies designs or patterns using a screen and ink.

In the context of road construction, surface treatment refers to the application of asphalt emulsion and aggregate to protect roads from moisture and sun exposure. This process adds skid resistance, prevents moisture intrusion, and provides an anti-glare surface during wet weather[3].

Chemical raw materials are essential components in the formulation of surface treatment additives. These materials include polymers, resins, and other compounds that provide specific properties to the additives. The choice of chemical raw material depends on the desired outcome, such as improved durability, adhesion, or resistance to environmental factors.

High polymer surface active agents are used to regulate interfacial tension between oil and water. These agents can be tailored to achieve precise control over surface properties by adjusting their composition and pH levels[4].

Surface treatment additives and techniques play a vital role in enhancing the performance and longevity of various materials. From flow and leveling agents in coatings to corrosion inhibitors and metal surface treatment techniques, these additives and methods are crucial for achieving desired surface properties. Understanding the different types of surface treatment additives and their applications is essential for selecting the right materials for specific industries and applications.

Answer: The primary types include PDMS (Polydimethylsiloxane) and acrylic flow and leveling agents. PDMS is widely used due to its effectiveness in reducing surface tension, while acrylic agents offer a silicone-free alternative[1].

Answer: Silicones improve the application, adherence, and durability of coatings by enhancing wetting, defoaming, and release characteristics. They are versatile and used in various industries[5].

Answer: Surfactants primarily improve pigment dispersion but also modify surface properties by enhancing adhesion and interaction between coatings and substrates[9].

Answer: Road surface treatment adds skid resistance, prevents moisture intrusion, and provides an anti-glare surface during wet weather. It is cost-effective and prolongs the lifespan of roads[3].

Answer: High polymer surface active agents regulate interfacial tension by adjusting their composition and pH levels. This allows for precise control over surface properties in oil-water systems[4].

[1] https://borchers.com/news-events-blog/how-to-choose-the-right-flow-leveling-additive-for-your-coatings/

[2] https://www.youtube.com/watch?v=JmkdmMfTYuA

[3] https://www.ptbocounty.ca/en/living/surface-treatment-faq.aspx

[4] https://patents.google.com/patent/CN111804238A/zh

[5] https://www.momentive.com/en-us/categories/coatings-additives

[6] https://www.youtube.com/watch?v=RELcdFBdtJw

[7] https://www.universalfireshield.com/faqsheets/paintfaq.pdf

[8] https://patents.google.com/patent/CN113544120B/zh

[9] https://coatings.specialchem.com/selection-guide/surface-modification-additives-for-coatings

[10] https://www.pcimag.com/ext/resources/AdditivesHandbook/PCI-Additive-Definitions-2011-SECURED.pdf

[11] https://www.byk.com/en/product/surface-additives

This article highlights the top stannous sulfate manufacturers and suppliers in the UK, focusing on their product quality, industrial applications, and market presence. It emphasizes the UK's strength in producing high-purity stannous sulfate for surface treatment, water treatment, and electroplating industries. Key players like REAXIS and Atotech lead the market with innovative solutions, while OEM support and regulatory compliance remain core advantages of UK suppliers. The article also addresses the compound's uses and includes a detailed FAQ to assist industry professionals.

Germany leads Europe in Stannous Sulfate manufacturing, supplying high-purity, reliable chemicals essential for electroplating, glass production, pharmaceuticals, and more. Key German suppliers like TIB Chemicals AG, MCC Menssing, Univar Solutions GmbH, and VMP Chemiekontor GmbH offer tailored solutions, strict quality control, and global distribution for diverse industrial demands.

This article explores the top stannous sulfate manufacturers and suppliers in Europe, highlighting leading companies like TIB Chemicals and Chimica Panzeri. It details production technologies, quality standards, industry applications, and OEM services, offering insights for markets requiring high-purity stannous sulfate chemicals.

This article explores the top stannous sulfate manufacturers and suppliers in France, highlighting their product quality, compliance with environmental standards, customized OEM services, and key industrial applications such as aluminum surface treatment, electronics, pharmaceuticals, and wastewater management.

This article explores the top stannous sulfate manufacturers and suppliers in America, detailing key companies, product forms, industries served, manufacturing processes, quality controls, and environmental considerations. It highlights the benefits of sourcing stannous sulfate locally with customization and technical support options. Insightful images illustrate stannous sulfate forms, production, and applications in industrial processes. Finally, a FAQ section addresses common queries related to stannous sulfate use and supply.

This comprehensive report explores Japan's top nickel sulfate manufacturers and suppliers, highlighting their production capabilities, market positions, and product applications. Featuring companies like Sumitomo Metal Mining and SEIDO Chemical Industry, the article delves into manufacturing processes, industry uses, and environmental practices, reflecting the pivotal role of Japanese firms in the advancing global nickel sulfate market.

South Korea is a leading global hub for nickel sulfate manufacturing, dominated by Korea Zinc and KEMCO with a combined annual capacity of 80,000 tons. Leveraging advanced smelting technologies and government-supported strategic status, these manufacturers supply high-quality nickel sulfate for electric vehicle batteries, surface treatment, and chemical industries. South Korean suppliers offer comprehensive OEM services to international clients, meeting growing global demand with innovation, sustainability, and quality.

This article provides a comprehensive overview of leading nickel sulfate manufacturers and suppliers in Portugal, covering their technological capabilities, product lines, market roles, and strict compliance with international standards. Highlighting diverse applications from electroplating to battery manufacturing, it showcases Portugal’s growing importance in the global nickel sulfate supply chain. Accompanied by relevant images, the article emphasizes sustainability, innovation, and quality as cornerstones of the Portuguese chemical sector.

This article explores the top nickel sulfate manufacturers and suppliers in Spain, highlighting their product offerings, quality standards, and strategic advantages. It covers Spanish industry applications, OEM services, and explains why Spain is a preferred sourcing hub for global chemical buyers. The article also includes detailed FAQs and relevant images to provide a comprehensive understanding of the nickel sulfate market in Spain.

Italy’s nickel sulfate manufacturing and supply chain is advanced, diverse, and globally integrated—supporting key industries like batteries, electroplating, and catalysts. With leading companies, customized services, and sustainable practices, Italian nickel sulfate manufacturers and suppliers are crucial to meeting the world’s growing demand for this essential chemical.

This article provides an in-depth overview of the top nickel sulfate manufacturers and suppliers in Russia, focusing on major companies like Norilsk Nickel, their production processes, market presence, environmental initiatives, and the diverse industrial applications of nickel sulfate. It serves as a valuable resource for international businesses looking to source high-quality nickel sulfate from Russia.

Aluminum alloys have become indispensable materials in modern industry, owing to their light weight, high strength-to-weight ratio, corrosion resistance, workability, and versatility. However, their durability—especially when used in challenging environments—is critically dependent on

Electrophoretic coatings, often referred to as *E-coatings* or *electrophoretic deposition (EPD)*, have revolutionized surface finishing in the modern manufacturing landscape. They blend chemistry, material science, and advanced technology to create coatings that are durable, uniform, and environmen

Discover Europe's most prominent Nickel Sulfate Manufacturers and Suppliers, including sustainability-focused innovators and rapid-response distributors serving the EV, electroplating, and advanced materials sectors. Learn about top companies, key trends, market drivers, and FAQs to inform your industrial chemical sourcing decisions. This comprehensive guide highlights the critical role nickel sulfate plays in Europe’s green industrial future.

This article details France’s leading role in nickel sulfate production, covering major manufacturers and suppliers, innovative production methods, sustainability commitments, and the industry’s critical role in green technology supply chains. It also examines market drivers, regulatory compliance, and supply chain strategies while answering common industry questions. The content is especially relevant for businesses seeking OEM solutions for aluminum profile treatment and battery production.

This comprehensive guide details the leading Nickel Sulfate Manufacturers and Suppliers in Germany, highlighting their strengths, product applications, and why Germany is a global leader. It covers selection criteria, market trends, and answers to key FAQs for buyers and industry professionals.

This article offers a comprehensive guide to the UK’s top Nickel Sulfate Manufacturers and Suppliers, highlighting industry applications, leading brands, and sourcing strategies in the rapidly growing British and global markets. From surface finishing to electric vehicle batteries, discover how to select the right partner and stay ahead of industry shifts.

This article explores the top Nickel Sulfate Manufacturers and Suppliers in America, highlighting their key products, application areas, and essentials of reliable sourcing. With detailed industry profiles, market trends, future outlooks, and FAQs, it serves as a vital comprehensive resource for businesses seeking high-quality nickel sulfate and dependable partnership.

Choosing the best chemical raw materials for aluminum profiles is **critical to ensuring strength, durability, corrosion resistance, and sustainability** in the final products. The selection impacts not only the mechanical and aesthetic qualities but also influences cost-effectiveness, production ef

In the global industrial landscape, **chemical raw materials for surface treatment** play a critically transformative role in enhancing the durability, functionality, and aesthetics of countless products. Surface treatment chemicals help prevent corrosion, improve adhesion, increase wear resistance,