Please Choose Your Language

Views: 222 Author: Carie Publish Time: 2025-07-24 Origin: Site

Content Menu

● Introduction to Nickel Sulfate and Its Industrial Importance

>> Applications of Nickel Sulfate

● The French Nickel Sulfate Industry: An Overview

● Leading Nickel Sulfate Manufacturers and Suppliers in France

>> 1. Sibanye-Stillwater (Sandouville Refinery)

>> 2. Eramet

>> 3. Other European Partners Serving the French Market

● Production Innovations in the Nickel Sulfate Sector

>> Adoption of Chloride Processing

>> Green Chemistry and Circular Economy Practices

>> Lab-Scale to Industrial-Scale Success

● Supply Chain and OEM Services

● Market Drivers and Challenges

>> Green Revolution and Energy Storage Growth

>> Regulatory Compliance and Environmental Responsibility

>> Global Supply Vulnerabilities and Supply Security

● Sustainability Efforts and Future Outlook

● FAQ

>> 1. What are the main uses of nickel sulfate?

>> 2. Why is battery-grade nickel sulfate important?

>> 3. What innovations are French manufacturers implementing in nickel sulfate production?

>> 4. How do nickel sulfate suppliers serve international clients?

>> 5. Is French nickel sulfate environmentally sustainable?

Nickel sulfate is a vital industrial chemical used in various applications—most notably in battery manufacturing (especially for electric vehicles), electroplating, chemical synthesis, and nickel surface finishing for aluminum and other metals. As the demand for electric vehicles and renewable energy rises, so does the need for high-quality nickel sulfate, making the role of manufacturers and suppliers more critical than ever. France, leveraging its robust chemical and metallurgical industry, has become home to some of Europe's most significant nickel sulfate manufacturers and suppliers.

Below, we explore the landscape of leading nickel sulfate manufacturers and suppliers in France, the growth drivers behind the industry, production innovations, supply chain challenges, sustainability efforts, and frequently asked questions. Throughout the article, you'll find visual illustrations to deepen your understanding of the subject.

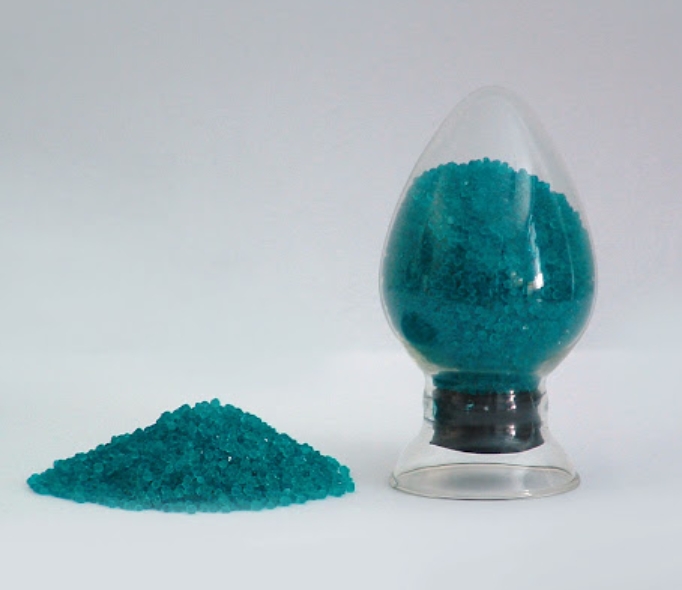

Nickel sulfate (NiSO4) is an inorganic compound, commonly encountered as a blue-green crystalline solid. Widely used in electroplating and as a precursor for producing cathode materials for lithium-ion batteries, nickel sulfate is a cornerstone of modern green technologies.

- Lithium-ion battery production: A primary component in the precursor cathode active material (pCAM).

- Electroplating: Vital for aluminum profiles, stainless steel, and other metals for both corrosion resistance and aesthetics.

- Metal surface treatment: Key for aluminum, enhancing property and finish.

- Chemical intermediates: Used in pigment, catalyst, and other chemical blends.

- Water treatment: Functions in wastewater purification and contamination control.

The versatility of nickel sulfate, along with its essential role in the electrification and surface finishing industries, has made it an indispensable chemical in modern manufacturing and sustainability efforts.

France stands out in Europe for several reasons:

- Robust chemical sector: France has a strong tradition in chemical process industries, including specialty chemicals.

- Strategic location: Proximity to major industrial clients across the EU and global shipping routes.

- Research and development: Strong focus on innovation, especially for green, energy-efficient processes.

- Commitment to sustainability: Strong environmental regulation and adoption of cleaner production methods.

- Government support and incentives: Encouragement for manufacturers adopting eco-friendly technologies.

The nickel sulfate industry in France reflects these advantages, serving both domestic demands and exporting to the broader European market and beyond.

Sibanye-Stillwater, a global mining and metals group, operates the Sandouville Refinery in France. This facility—originally owned by Eramet—was acquired to focus primarily on producing high-purity nickel sulfate intended for the European battery supply chain.

The Sandouville plant leverages advanced chloride processing, with ongoing repurposing and technological upgrades to cater to the lithium-ion battery market. Sibanye's innovations allow for the production of precursor cathode active material (pCAM) using energy-efficient chloride routes, reducing waste, emissions, and costs. The refinery is at the forefront of “brownfield” transformation—adapting existing processes to meet the growing demand for nickel sulfate in Europe.

The company also emphasizes vertically integrated supply chains, securing raw materials and refining processes to stabilize product quality and supply reliability. Through collaboration with automotive and energy storage manufacturers, Sibanye-Stillwater plays a pivotal role in Europe's transition to green energy.

Eramet is one of the world's leading mining and metallurgical companies, with a rich history in nickel extraction and processing. While much of their nickel mining is concentrated in New Caledonia and Indonesia, their European expertise and processing plants contribute heavily to the French and European markets.

Though Eramet's direct nickel sulfate production is limited in France, their expertise in upstream mining, ferronickel production, and processing makes them a crucial part of the regional value chain, supplying intermediates for further nickel sulfate synthesis. Their sustainable mining initiatives and investment in innovation ensure responsible sourcing and environmental compliance.

Large companies in neighboring countries also actively serve the French nickel sulfate market:

- Chemical manufacturers and trading firms in Germany, Belgium, and Austria supply raw materials and specialty products.

- Local distributors offer OEM and custom formulations tailored to applications such as aluminum profile finishing, battery-grade chemicals, and wastewater treatment.

- Partnerships between these European firms and French manufacturers ensure a consistent and diverse product portfolio, meeting varying industrial demands.

This interconnected network promotes strong industry resilience and supports France's central role in the European nickel sulfate supply chain.

One of the most significant industry shifts is the move from traditional sulfate-based production to chloride-based methods. This change promises:

- Fewer processing steps.

- Higher yield and purity.

- Reduced carbon emissions.

- Lower energy consumption.

- Decreased waste volume.

A prime example is the Sandouville refinery, which is exploring direct pCAM synthesis from mixed hydroxide precipitate (MHP) in a chloride medium—a method that is both energy and cost-effective. This innovative process reduces the chemical footprint of nickel sulfate production and enhances its suitability for battery-grade applications.

French manufacturers increasingly integrate the principles of green chemistry and circular economy into nickel sulfate production:

- Recycling nickel from battery waste and industrial residues.

- Utilizing renewable energy sources to power manufacturing plants.

- Minimization of water use and efficient wastewater treatment within plants.

- Recovery and reuse of process chemicals.

These measures not only improve environmental sustainability but also help manage costs and meet rising regulations.

Recent achievements include the successful scale-up of novel precursor cathode active material (pCAM) production from laboratory to industrial scale. New patents protect these innovations, positioning French companies as leaders in cutting-edge nickel sulfate technology. Such progress is fundamental to meeting the stringent quality and volume demands of the electric vehicle manufacturing sector.

Many Nickel Sulfate Manufacturers and Suppliers in France and Europe provide comprehensive OEM (Original Equipment Manufacturer) services, including:

- Custom formulation to meet unique client specifications.

- Private labeling and packaging solutions.

- Tailored logistics and distribution strategies worldwide.

These services cater to clients ranging from automotive OEMs to surface treatment companies and water purification system manufacturers.

Key factors contributing to sector success include:

- An extensive product range with over 300 chemical additives and raw materials.

- Strict quality control and certifications, including ISO standards and REACH compliance.

- Responsive customer support addressing technical, regulatory, and logistical inquiries.

- A commitment to transparent and ethical sourcing practices.

This combination of capabilities strengthens the position of French manufacturers and suppliers as trusted partners in global supply chains.

The accelerating adoption of electric vehicles (EVs) and renewable energy storage solutions has transformed demand dynamics for nickel sulfate. Battery-grade nickel sulfate requires increasingly stringent purity, consistency, and performance standards.

This growth drives investment in:

- Enhanced refining technologies.

- Supply chain fortification against price and volume volatility.

- Research on next-generation battery chemistries less reliant on scarce raw materials.

Strict European Union regulations concerning chemical safety, emissions, and environmental protection compel manufacturers to adopt cleaner, sustainable production technologies. These include:

- Reduction of hazardous byproducts and effluents.

- Minimizing occupational health risks.

- Transparent reporting and traceability along the supply chain.

Alongside compliance, these regulations encourage innovation and corporate responsibility.

Despite its strengths, France's nickel sulfate industry depends on globally mined nickel concentrate, exposing it to risks like:

- Geopolitical tensions affecting mining supply.

- Price volatility in nickel commodities.

- Disruptions from trade policies or logistics constraints.

To mitigate this, French producers are enhancing supply chain diversification, increasing recycling efforts, and exploring partnerships with stable mining jurisdictions.

The decarbonization of industry and transportation sectors underscores the importance of nickel sulfate manufacturers in France. The future outlook includes:

- Expanding capacity for battery-grade nickel sulfate to meet EV industry growth.

- Integration of advanced analytics and Industry 4.0 technologies for improved production efficiency.

- Continuous research into alternative, less environmentally impactful nickel extraction and processing methods.

- Strengthened collaboration between manufacturers, automotive OEMs, government bodies, and research institutions.

France aims to position itself as a leading hub for sustainable and innovative nickel sulfate production, profoundly impacting the European green industrial ecosystem.

France's nickel sulfate industry is at the heart of Europe's green energy and advanced manufacturing sectors. Through pioneering companies like Sibanye-Stillwater and Eramet, as well as a robust network of suppliers and distributors, France is shaping the continent's transition to cleaner energy and high-performance material applications. The industry's focus on innovation, sustainability, and supply chain excellence ensures it remains competitive globally.

Whether you are a brand owner, wholesaler, or manufacturer seeking OEM partners for nickel sulfate and related chemical solutions, France remains a center of expertise and reliability. As EVs and high-performance batteries continue to drive demand, Nickel Sulfate Manufacturers and Suppliers are scaling up to deliver quality, consistency, and environmental stewardship.

Nickel sulfate is essential in battery manufacturing (especially for lithium-ion batteries), electroplating, surface finishing of aluminum profiles, chemical synthesis, and as a reagent in water treatment processes.

Battery-grade nickel sulfate must meet strict purity and composition standards to ensure the safe and efficient operation of lithium-ion batteries used in electric vehicles and energy storage systems.

French manufacturers are moving towards chloride-based processing, integrating patented methods for direct synthesis from new feedstocks, and focusing on energy efficiency and reduced waste.

Suppliers offer OEM services, custom formulations, and private labeling, with robust logistics and support for technical, regulatory, and quality requirements, making them ideal partners for global brands and distributors.

Yes. French manufacturers prioritize green chemistry, reduce emissions, and adopt innovations that raise energy efficiency and cut waste, aligning with strict EU regulations for chemical production.

Aluminum alloys have become indispensable materials in modern industry, owing to their light weight, high strength-to-weight ratio, corrosion resistance, workability, and versatility. However, their durability—especially when used in challenging environments—is critically dependent on

Electrophoretic coatings, often referred to as *E-coatings* or *electrophoretic deposition (EPD)*, have revolutionized surface finishing in the modern manufacturing landscape. They blend chemistry, material science, and advanced technology to create coatings that are durable, uniform, and environmen

Discover Europe's most prominent Nickel Sulfate Manufacturers and Suppliers, including sustainability-focused innovators and rapid-response distributors serving the EV, electroplating, and advanced materials sectors. Learn about top companies, key trends, market drivers, and FAQs to inform your industrial chemical sourcing decisions. This comprehensive guide highlights the critical role nickel sulfate plays in Europe’s green industrial future.

This article details France’s leading role in nickel sulfate production, covering major manufacturers and suppliers, innovative production methods, sustainability commitments, and the industry’s critical role in green technology supply chains. It also examines market drivers, regulatory compliance, and supply chain strategies while answering common industry questions. The content is especially relevant for businesses seeking OEM solutions for aluminum profile treatment and battery production.

This comprehensive guide details the leading Nickel Sulfate Manufacturers and Suppliers in Germany, highlighting their strengths, product applications, and why Germany is a global leader. It covers selection criteria, market trends, and answers to key FAQs for buyers and industry professionals.

This article offers a comprehensive guide to the UK’s top Nickel Sulfate Manufacturers and Suppliers, highlighting industry applications, leading brands, and sourcing strategies in the rapidly growing British and global markets. From surface finishing to electric vehicle batteries, discover how to select the right partner and stay ahead of industry shifts.

This article explores the top Nickel Sulfate Manufacturers and Suppliers in America, highlighting their key products, application areas, and essentials of reliable sourcing. With detailed industry profiles, market trends, future outlooks, and FAQs, it serves as a vital comprehensive resource for businesses seeking high-quality nickel sulfate and dependable partnership.

Choosing the best chemical raw materials for aluminum profiles is **critical to ensuring strength, durability, corrosion resistance, and sustainability** in the final products. The selection impacts not only the mechanical and aesthetic qualities but also influences cost-effectiveness, production ef

In the global industrial landscape, **chemical raw materials for surface treatment** play a critically transformative role in enhancing the durability, functionality, and aesthetics of countless products. Surface treatment chemicals help prevent corrosion, improve adhesion, increase wear resistance,

Aluminum stands out in the materials world due to its combination of light weight, high strength-to-weight ratio, and natural corrosion resistance. Yet, despite its excellent surface passivation, aluminum's vulnerability in aggressive environments, such as marine or industrial atmospheres, necessita

Aluminum alloys have revolutionized modern engineering, offering unmatched versatility, lightness, and strength. But the secret to their remarkable properties lies in the careful selection and combination of raw materials. This comprehensive guide explores the best chemical raw materials for aluminu

Aluminum is a cornerstone of modern manufacturing, renowned for its exceptional strength-to-weight ratio, corrosion resistance, and versatility. However, to realize its full potential in diverse industrial applications, **surface treatment** is essential. Surface treatments enhance al

In modern chemistry and materials engineering, chemical raw materials and electrophoretic materials play crucial but distinct roles. While chemical raw materials refer broadly to the fundamental substances used to create chemicals, polymers, coatings, and various compounds, el

Metal treatment is a foundational process in countless industries, from automotive to aerospace, construction, electronics, and consumer goods. The selection of the right chemical raw materials is paramount; it determines not only the quality, performance, and longevity of the finished product but a

Aluminum profiles are fundamental components across modern industries—from construction and transportation to electronics and advanced manufacturing. The secret to their performance, longevity, and aesthetics lies not just in mec

Incomplete neutralization and descaling of aluminum profiles may be caused by the following factors:1. Process Parameter Issues: Such as insufficient treatment time, inappropriate temperature, or inaccurate solution concentration. If the treatment time is too short, the neutralization and descaling

After aluminum alloy undergoes anodizing treatment, an oxide film is formed that is resistant to oxidation, rust, corrosion, and wear. Furthermore, this oxide film is extremely stable in natural ecological environments, effectively protecting the surface of aluminum alloy products. The outer layer o

This article provides a comprehensive overview of the top sodium hydroxide manufacturers and suppliers in the UK, highlighting their products, specializations, and service features for various industries. It is designed to guide OEMs, resellers, and end-users in making informed choices and ensuring consistent access to high-quality sodium hydroxide. Covering market trends, safety, packaging, and FAQs, the article is an essential resource for anyone in need of sodium hydroxide in the UK market.

This article provides an in-depth overview of the top sodium hydroxide manufacturers and suppliers in Japan. It highlights key companies such as Tosoh Corporation, Shin-Etsu Chemical, Tokuyama Corporation, Sumitomo Chemical, and Kureha Corporation, detailing their production facilities, technologies, and industrial applications. The article also covers the importance of OEM services, environmental initiatives, and future industry trends, offering valuable insights for global businesses seeking reliable chemical partners.

This article provides an in-depth look at the top sodium hydroxide manufacturers and suppliers in South Korea. It covers their product types, industrial applications, technological strengths, quality certifications, environmental practices, and supply chain capabilities. Leading companies like OCI and YOUNG JIN CHEMICAL are highlighted for their innovation and reliability in supplying high-purity caustic soda to global markets.