Please Choose Your Language

Views: 222 Author: Carie Publish Time: 2025-02-16 Origin: Site

Content Menu

● Impact of Sewage Treatment on Public Health

>> Reduction of Waterborne Diseases

>> Prevention of Environmental Contamination

>> Improved Sanitation and Hygiene

● Challenges in Wastewater Management

● Future Directions in Wastewater Management

● FAQ

>> 1. What are the main stages of sewage treatment?

>> 2. How does sewage treatment protect public health?

>> 3. What are some of the challenges in wastewater management?

>> 4. What are some innovative approaches to wastewater management?

>> 5. How can individuals contribute to effective sewage treatment?

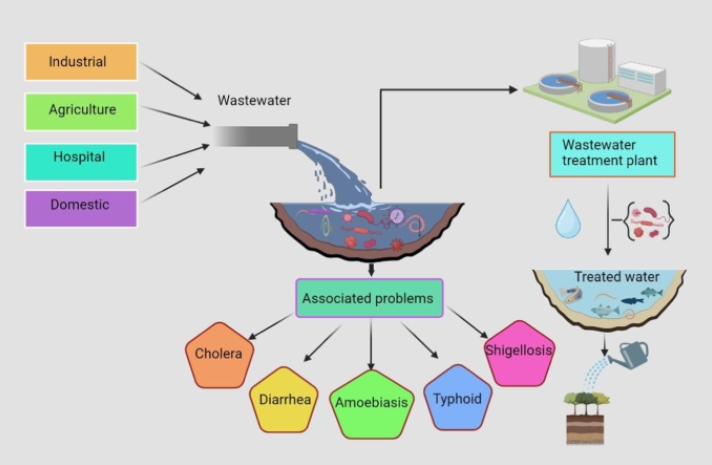

Sewage treatment is a critical process for protecting public health and the environment. Untreated sewage contains a variety of harmful contaminants, including pathogens, bacteria, viruses, and parasites, as well as chemical pollutants that can contaminate water sources and cause disease[1][7]. Effective sewage treatment removes these contaminants, producing effluent that is safe for discharge into the environment and protecting public health[5]. This article explores the various stages of sewage treatment, its impact on public health, and the challenges and future directions in wastewater management, integrating illustrative figures, videos, and frequently asked questions to provide a comprehensive overview.

Sewage treatment plants employ a combination of physical, chemical, and biological processes to remove contaminants from wastewater[5]. The treatment process typically involves several stages:

1. Preliminary Treatment: This initial stage removes large debris, such as diapers, sanitary napkins, and plastic bags, that can damage or clog treatment equipment[2]. Pre-screening involves the use of screens to capture these materials, followed by grit removal to eliminate sand and gravel[2].

2. Primary Treatment: Primary treatment involves the separation of solid organic matter from wastewater[2]. Wastewater is held in large sedimentation tanks, where the heavy solid particles settle to the bottom, forming a layer of sludge[2]. This sludge is then removed for further treatment or disposal.

3. Secondary Treatment: Secondary treatment focuses on removing dissolved and suspended organic matter that remains after primary treatment[2]. This is typically achieved through biological processes, such as the activated sludge method, where microorganisms break down the organic pollutants[2].

4. Tertiary Treatment: Tertiary treatment, also known as advanced treatment, removes any remaining pollutants, such as nutrients and pathogens, to meet specific water quality standards[2]. This may involve filtration, disinfection, and nutrient removal processes.

5. Sludge Treatment: Sludge, the solid material removed during primary and secondary treatment, requires further processing to reduce its volume and stabilize the organic matter[2]. Sludge treatment processes may include thickening, digestion, and dewatering.

Effective sewage treatment has a significant impact on public health by reducing the risk of waterborne diseases and environmental contamination[1][4].

Untreated sewage can contaminate drinking water sources, leading to outbreaks of waterborne diseases such as cholera, typhoid fever, and dysentery[1]. Sewage treatment removes pathogens and other contaminants, making the water safe for human consumption[4]. Studies have shown that increased access to wastewater treatment reduces disease mortality, independent of income or sanitation levels[4].

Sewage treatment prevents the contamination of rivers, lakes, and coastal waters with harmful pollutants[1]. Untreated sewage can cause eutrophication, the excessive enrichment of water bodies with nutrients, leading to algal blooms and oxygen depletion, which can harm aquatic life[2]. Sewage treatment removes nutrients and other pollutants, protecting aquatic ecosystems and recreational water resources[1].

Sewage treatment contributes to improved sanitation and hygiene by providing a safe and effective means of managing human waste[1]. Proper sewage disposal reduces the risk of exposure to fecal matter, which can transmit a variety of infectious diseases[7].

Despite the significant benefits of sewage treatment, there are several challenges in wastewater management:

- Aging Infrastructure: Many wastewater treatment plants are aging and in need of repair or replacement[1]. This can lead to reduced treatment efficiency and increased risk of equipment failures and overflows[1].

- Increasing Population: Growing populations are placing increased demands on wastewater treatment facilities[1]. Many plants are operating at or near capacity, making it difficult to meet the needs of their communities[1].

- Emerging Contaminants: New and emerging contaminants, such as pharmaceuticals and personal care products, are increasingly being detected in wastewater[7]. These contaminants may not be effectively removed by conventional treatment processes, posing potential risks to human health and the environment[7].

- Climate Change: Climate change is exacerbating the challenges of wastewater management[7]. Increased rainfall and flooding can overwhelm treatment plants, leading to overflows and the release of untreated sewage into the environment[7].

To address these challenges, several innovative approaches are being developed for wastewater management:

- Decentralized Treatment Systems: Decentralized treatment systems, such as septic systems and constructed wetlands, can provide cost-effective and sustainable wastewater treatment for smaller communities and individual households[2].

- Advanced Treatment Technologies: Advanced treatment technologies, such as membrane filtration and advanced oxidation processes, can remove a wider range of contaminants, including emerging pollutants, from wastewater[2].

- Water Reuse: Water reuse involves treating wastewater to a level suitable for non-potable uses, such as irrigation, industrial cooling, and toilet flushing[3]. This can help conserve water resources and reduce the demand on freshwater supplies[3].

- Resource Recovery: Wastewater contains valuable resources, such as nutrients and energy, that can be recovered and reused[3]. Nutrient recovery technologies can extract phosphorus and nitrogen from wastewater for use as fertilizers, while anaerobic digestion can convert organic matter into biogas, a renewable energy source[3].

Sewage treatment plays a vital role in protecting public health and the environment by removing harmful contaminants from wastewater[4]. Effective sewage treatment reduces the risk of waterborne diseases, prevents environmental contamination, and improves sanitation and hygiene[1][7]. While there are challenges in wastewater management, such as aging infrastructure, increasing population, emerging contaminants, and climate change, innovative approaches are being developed to address these challenges and create more sustainable wastewater management systems[1].

The main stages of sewage treatment are preliminary treatment, primary treatment, secondary treatment, and tertiary treatment. Preliminary treatment removes large debris, primary treatment separates solid organic matter, secondary treatment removes dissolved organic matter, and tertiary treatment removes remaining pollutants[2].

Sewage treatment protects public health by removing pathogens and other contaminants from wastewater, making it safe for discharge into the environment and reducing the risk of waterborne diseases[4].

Some of the challenges in wastewater management include aging infrastructure, increasing population, emerging contaminants, and climate change[1][7].

Some innovative approaches to wastewater management include decentralized treatment systems, advanced treatment technologies, water reuse, and resource recovery[2][3].

Individuals can contribute to effective sewage treatment by properly disposing of waste, conserving water, and avoiding the discharge of harmful chemicals into the sewer system[2].

[1] https://raeng.org.uk/news/new-report-urges-upgrades-in-wastewater-infrastructure-to-protect-public-health

[2] https://www.netsolwater.com/understanding-of-a-sewage-treatment-plant-via-diagram.php?blog=1243

[3] https://www.mdpi.com/2071-1050/15/14/10940

[4] https://pubmed.ncbi.nlm.nih.gov/22744697/

[5] https://www.youtube.com/watch?v=GYzhh01h5K4

[6] https://pmc.ncbi.nlm.nih.gov/articles/PMC7349760/

[7] https://pubmed.ncbi.nlm.nih.gov/34216613/

[8] https://www.coldwater.org/272/The-Wastewater-Treatment-Process

[9] https://legacy.winnipeg.ca/finance/findata/matmgt/documents/2012/682-2012/682-2012_Appendix_G-SEWPCC_Upgradin_Expansion_Conceptual_Design_Report/Sec_6_PFDMassBal_Jun0109.pdf

Italy plays a crucial role in the European and global stannous sulfate industry, with leading manufacturers and suppliers offering top-quality, customized products for electroplating, glass, construction, water treatment, pharmaceuticals, and other advanced sectors. Their compliance, innovation, and sustainable practices make them partners of choice for international clients seeking reliable chemical solutions that meet stringent quality and environmental standards.

This article highlights the top stannous sulfate manufacturers and suppliers in the UK, focusing on their product quality, industrial applications, and market presence. It emphasizes the UK's strength in producing high-purity stannous sulfate for surface treatment, water treatment, and electroplating industries. Key players like REAXIS and Atotech lead the market with innovative solutions, while OEM support and regulatory compliance remain core advantages of UK suppliers. The article also addresses the compound's uses and includes a detailed FAQ to assist industry professionals.

Germany leads Europe in Stannous Sulfate manufacturing, supplying high-purity, reliable chemicals essential for electroplating, glass production, pharmaceuticals, and more. Key German suppliers like TIB Chemicals AG, MCC Menssing, Univar Solutions GmbH, and VMP Chemiekontor GmbH offer tailored solutions, strict quality control, and global distribution for diverse industrial demands.

This article explores the top stannous sulfate manufacturers and suppliers in Europe, highlighting leading companies like TIB Chemicals and Chimica Panzeri. It details production technologies, quality standards, industry applications, and OEM services, offering insights for markets requiring high-purity stannous sulfate chemicals.

This article explores the top stannous sulfate manufacturers and suppliers in France, highlighting their product quality, compliance with environmental standards, customized OEM services, and key industrial applications such as aluminum surface treatment, electronics, pharmaceuticals, and wastewater management.

This article explores the top stannous sulfate manufacturers and suppliers in America, detailing key companies, product forms, industries served, manufacturing processes, quality controls, and environmental considerations. It highlights the benefits of sourcing stannous sulfate locally with customization and technical support options. Insightful images illustrate stannous sulfate forms, production, and applications in industrial processes. Finally, a FAQ section addresses common queries related to stannous sulfate use and supply.

This comprehensive report explores Japan's top nickel sulfate manufacturers and suppliers, highlighting their production capabilities, market positions, and product applications. Featuring companies like Sumitomo Metal Mining and SEIDO Chemical Industry, the article delves into manufacturing processes, industry uses, and environmental practices, reflecting the pivotal role of Japanese firms in the advancing global nickel sulfate market.

South Korea is a leading global hub for nickel sulfate manufacturing, dominated by Korea Zinc and KEMCO with a combined annual capacity of 80,000 tons. Leveraging advanced smelting technologies and government-supported strategic status, these manufacturers supply high-quality nickel sulfate for electric vehicle batteries, surface treatment, and chemical industries. South Korean suppliers offer comprehensive OEM services to international clients, meeting growing global demand with innovation, sustainability, and quality.

This article provides a comprehensive overview of leading nickel sulfate manufacturers and suppliers in Portugal, covering their technological capabilities, product lines, market roles, and strict compliance with international standards. Highlighting diverse applications from electroplating to battery manufacturing, it showcases Portugal’s growing importance in the global nickel sulfate supply chain. Accompanied by relevant images, the article emphasizes sustainability, innovation, and quality as cornerstones of the Portuguese chemical sector.

This article explores the top nickel sulfate manufacturers and suppliers in Spain, highlighting their product offerings, quality standards, and strategic advantages. It covers Spanish industry applications, OEM services, and explains why Spain is a preferred sourcing hub for global chemical buyers. The article also includes detailed FAQs and relevant images to provide a comprehensive understanding of the nickel sulfate market in Spain.

Italy’s nickel sulfate manufacturing and supply chain is advanced, diverse, and globally integrated—supporting key industries like batteries, electroplating, and catalysts. With leading companies, customized services, and sustainable practices, Italian nickel sulfate manufacturers and suppliers are crucial to meeting the world’s growing demand for this essential chemical.

This article provides an in-depth overview of the top nickel sulfate manufacturers and suppliers in Russia, focusing on major companies like Norilsk Nickel, their production processes, market presence, environmental initiatives, and the diverse industrial applications of nickel sulfate. It serves as a valuable resource for international businesses looking to source high-quality nickel sulfate from Russia.

Aluminum alloys have become indispensable materials in modern industry, owing to their light weight, high strength-to-weight ratio, corrosion resistance, workability, and versatility. However, their durability—especially when used in challenging environments—is critically dependent on

Electrophoretic coatings, often referred to as *E-coatings* or *electrophoretic deposition (EPD)*, have revolutionized surface finishing in the modern manufacturing landscape. They blend chemistry, material science, and advanced technology to create coatings that are durable, uniform, and environmen

Discover Europe's most prominent Nickel Sulfate Manufacturers and Suppliers, including sustainability-focused innovators and rapid-response distributors serving the EV, electroplating, and advanced materials sectors. Learn about top companies, key trends, market drivers, and FAQs to inform your industrial chemical sourcing decisions. This comprehensive guide highlights the critical role nickel sulfate plays in Europe’s green industrial future.

This article details France’s leading role in nickel sulfate production, covering major manufacturers and suppliers, innovative production methods, sustainability commitments, and the industry’s critical role in green technology supply chains. It also examines market drivers, regulatory compliance, and supply chain strategies while answering common industry questions. The content is especially relevant for businesses seeking OEM solutions for aluminum profile treatment and battery production.

This comprehensive guide details the leading Nickel Sulfate Manufacturers and Suppliers in Germany, highlighting their strengths, product applications, and why Germany is a global leader. It covers selection criteria, market trends, and answers to key FAQs for buyers and industry professionals.

This article offers a comprehensive guide to the UK’s top Nickel Sulfate Manufacturers and Suppliers, highlighting industry applications, leading brands, and sourcing strategies in the rapidly growing British and global markets. From surface finishing to electric vehicle batteries, discover how to select the right partner and stay ahead of industry shifts.

This article explores the top Nickel Sulfate Manufacturers and Suppliers in America, highlighting their key products, application areas, and essentials of reliable sourcing. With detailed industry profiles, market trends, future outlooks, and FAQs, it serves as a vital comprehensive resource for businesses seeking high-quality nickel sulfate and dependable partnership.

Choosing the best chemical raw materials for aluminum profiles is **critical to ensuring strength, durability, corrosion resistance, and sustainability** in the final products. The selection impacts not only the mechanical and aesthetic qualities but also influences cost-effectiveness, production ef