Please Choose Your Language

Views: 222 Author: Carie Publish Time: 2025-02-24 Origin: Site

Content Menu

● Introduction to Chemical Raw Materials

>> Biomass-Based Raw Materials

● Environmental Challenges of Chemical Raw Materials

● Sustainable Practices in the Chemical Industry

● FAQ

>> 1. What are the primary environmental challenges associated with chemical raw materials?

>> 3. What role does green chemistry play in sustainable chemical production?

>> 4. How can the chemical industry implement a circular economy?

>> 5. What are some renewable energy sources being adopted in the chemical industry?

● Citation

The chemical industry plays a pivotal role in modern society, providing essential raw materials for a wide range of products, from pharmaceuticals and plastics to construction materials and electronics. However, this industry also poses significant environmental challenges due to its reliance on energy-intensive processes and the generation of hazardous byproducts. In this article, we will explore the role of chemical raw materials in environmental sustainability, highlighting both the challenges and potential solutions.

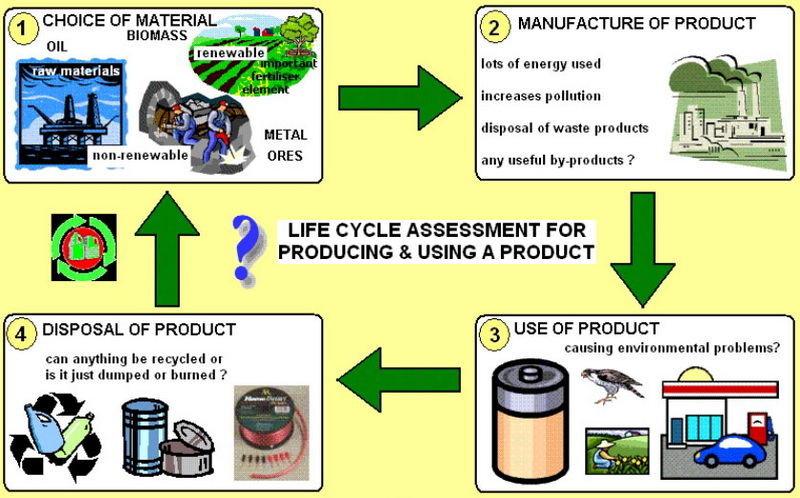

Chemical raw materials are the foundation of the chemical industry, serving as the starting point for the production of various chemicals and products. These materials can be derived from fossil fuels, biomass, or other natural resources. The choice of raw material significantly influences the environmental impact of chemical production, as different materials have varying levels of sustainability and environmental footprint.

Fossil-based raw materials, such as petroleum and natural gas, are the most commonly used sources for chemical production. However, their use contributes to greenhouse gas emissions and resource depletion, making them less sustainable in the long term[5].

Biomass-based raw materials offer a more sustainable alternative. Biomass can be converted into biofuels and biochemicals, reducing dependence on fossil fuels and potentially lowering greenhouse gas emissions[1].

The use of chemical raw materials poses several environmental challenges:

1. Energy Consumption and Greenhouse Gas Emissions: Chemical production processes are energy-intensive, leading to significant greenhouse gas emissions[4].

2. Water Pollution: Chemical manufacturing facilities often discharge wastewater containing toxic substances, posing risks to aquatic ecosystems and human health[2].

3. Solid Waste Generation: The industry generates significant amounts of solid waste, including hazardous byproducts that require proper disposal[8].

To address these environmental challenges, the chemical industry is adopting sustainable practices:

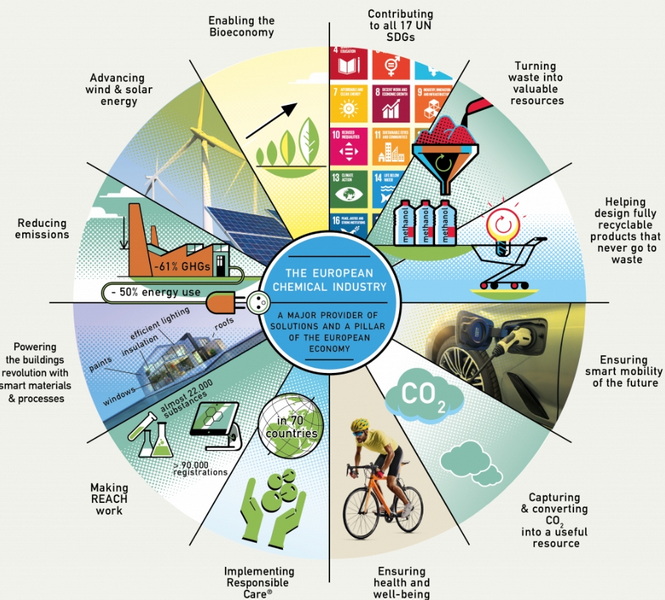

1. Green Chemistry: This approach focuses on designing chemical processes and products that minimize the use of hazardous substances and reduce energy consumption[6].

2. Circular Economy: Implementing closed-loop systems where waste is recycled or repurposed to minimize waste generation and enhance resource efficiency[7].

3. Renewable Energy Sources: Transitioning to renewable energy sources like solar and wind power to reduce reliance on fossil fuels[4].

Chemical raw materials play a crucial role in the sustainability of the chemical industry. While traditional fossil-based materials contribute to environmental challenges, biomass-based alternatives offer a more sustainable future. By adopting green chemistry principles, embracing the circular economy, and transitioning to renewable energy sources, the industry can significantly reduce its environmental footprint. Collaboration among stakeholders and regulatory compliance are essential for implementing these sustainable practices effectively.

Chemical raw materials contribute to energy consumption, greenhouse gas emissions, water pollution, and solid waste generation. These challenges can be mitigated by adopting sustainable practices such as green chemistry and the circular economy.

Biomass-based raw materials are generally more sustainable as they reduce dependence on fossil fuels and can lower greenhouse gas emissions. However, their full life cycle impacts, including agricultural practices and transportation emissions, must be considered.

Green chemistry focuses on designing chemical processes and products that minimize the use of hazardous substances, reduce energy consumption, and promote non-toxic circular material flows. This approach is crucial for reducing pollution and enhancing sustainability in the chemical industry.

The chemical industry can implement a circular economy by adopting closed-loop systems where waste is recycled or repurposed. This involves waste reduction strategies, recycling programs, and responsible disposal methods to minimize waste generation and enhance resource efficiency.

Renewable energy sources such as solar and wind power are being increasingly adopted to reduce the industry's reliance on fossil fuels and lower greenhouse gas emissions.

[1] https://www.elsevier.com/industry/sustainable-manufacturing-in-chemicals-industry

[2] https://www.alliedacademies.org/articles/environmental-impacts-and-mitigation-strategies-in-chemical-manufacturing.pdf

[3] https://www.mdpi.com/2071-1050/15/18/14014

[4] https://www.patsnap.com/resources/blog/sustainability-in-the-chemical-industry-challenges-and-solutions/

[5] https://phys.org/news/2022-02-production-chemicals-interfering-nature-absolute.html

[6] https://www.unep.org/topics/chemicals-and-pollution-action/circularity-sectors/green-and-sustainable-chemistry

[7] https://intimedia.id/read/sustainable-practices-in-the-chemical-industry-balancing-environmental-responsibility-and-business-growth

[8] https://www.deskera.com/blog/environmental-impact-of-chemical-production/

Italy plays a crucial role in the European and global stannous sulfate industry, with leading manufacturers and suppliers offering top-quality, customized products for electroplating, glass, construction, water treatment, pharmaceuticals, and other advanced sectors. Their compliance, innovation, and sustainable practices make them partners of choice for international clients seeking reliable chemical solutions that meet stringent quality and environmental standards.

This article highlights the top stannous sulfate manufacturers and suppliers in the UK, focusing on their product quality, industrial applications, and market presence. It emphasizes the UK's strength in producing high-purity stannous sulfate for surface treatment, water treatment, and electroplating industries. Key players like REAXIS and Atotech lead the market with innovative solutions, while OEM support and regulatory compliance remain core advantages of UK suppliers. The article also addresses the compound's uses and includes a detailed FAQ to assist industry professionals.

Germany leads Europe in Stannous Sulfate manufacturing, supplying high-purity, reliable chemicals essential for electroplating, glass production, pharmaceuticals, and more. Key German suppliers like TIB Chemicals AG, MCC Menssing, Univar Solutions GmbH, and VMP Chemiekontor GmbH offer tailored solutions, strict quality control, and global distribution for diverse industrial demands.

This article explores the top stannous sulfate manufacturers and suppliers in Europe, highlighting leading companies like TIB Chemicals and Chimica Panzeri. It details production technologies, quality standards, industry applications, and OEM services, offering insights for markets requiring high-purity stannous sulfate chemicals.

This article explores the top stannous sulfate manufacturers and suppliers in France, highlighting their product quality, compliance with environmental standards, customized OEM services, and key industrial applications such as aluminum surface treatment, electronics, pharmaceuticals, and wastewater management.

This article explores the top stannous sulfate manufacturers and suppliers in America, detailing key companies, product forms, industries served, manufacturing processes, quality controls, and environmental considerations. It highlights the benefits of sourcing stannous sulfate locally with customization and technical support options. Insightful images illustrate stannous sulfate forms, production, and applications in industrial processes. Finally, a FAQ section addresses common queries related to stannous sulfate use and supply.

This comprehensive report explores Japan's top nickel sulfate manufacturers and suppliers, highlighting their production capabilities, market positions, and product applications. Featuring companies like Sumitomo Metal Mining and SEIDO Chemical Industry, the article delves into manufacturing processes, industry uses, and environmental practices, reflecting the pivotal role of Japanese firms in the advancing global nickel sulfate market.

South Korea is a leading global hub for nickel sulfate manufacturing, dominated by Korea Zinc and KEMCO with a combined annual capacity of 80,000 tons. Leveraging advanced smelting technologies and government-supported strategic status, these manufacturers supply high-quality nickel sulfate for electric vehicle batteries, surface treatment, and chemical industries. South Korean suppliers offer comprehensive OEM services to international clients, meeting growing global demand with innovation, sustainability, and quality.

This article provides a comprehensive overview of leading nickel sulfate manufacturers and suppliers in Portugal, covering their technological capabilities, product lines, market roles, and strict compliance with international standards. Highlighting diverse applications from electroplating to battery manufacturing, it showcases Portugal’s growing importance in the global nickel sulfate supply chain. Accompanied by relevant images, the article emphasizes sustainability, innovation, and quality as cornerstones of the Portuguese chemical sector.

This article explores the top nickel sulfate manufacturers and suppliers in Spain, highlighting their product offerings, quality standards, and strategic advantages. It covers Spanish industry applications, OEM services, and explains why Spain is a preferred sourcing hub for global chemical buyers. The article also includes detailed FAQs and relevant images to provide a comprehensive understanding of the nickel sulfate market in Spain.

Italy’s nickel sulfate manufacturing and supply chain is advanced, diverse, and globally integrated—supporting key industries like batteries, electroplating, and catalysts. With leading companies, customized services, and sustainable practices, Italian nickel sulfate manufacturers and suppliers are crucial to meeting the world’s growing demand for this essential chemical.

This article provides an in-depth overview of the top nickel sulfate manufacturers and suppliers in Russia, focusing on major companies like Norilsk Nickel, their production processes, market presence, environmental initiatives, and the diverse industrial applications of nickel sulfate. It serves as a valuable resource for international businesses looking to source high-quality nickel sulfate from Russia.

Aluminum alloys have become indispensable materials in modern industry, owing to their light weight, high strength-to-weight ratio, corrosion resistance, workability, and versatility. However, their durability—especially when used in challenging environments—is critically dependent on

Electrophoretic coatings, often referred to as *E-coatings* or *electrophoretic deposition (EPD)*, have revolutionized surface finishing in the modern manufacturing landscape. They blend chemistry, material science, and advanced technology to create coatings that are durable, uniform, and environmen

Discover Europe's most prominent Nickel Sulfate Manufacturers and Suppliers, including sustainability-focused innovators and rapid-response distributors serving the EV, electroplating, and advanced materials sectors. Learn about top companies, key trends, market drivers, and FAQs to inform your industrial chemical sourcing decisions. This comprehensive guide highlights the critical role nickel sulfate plays in Europe’s green industrial future.

This article details France’s leading role in nickel sulfate production, covering major manufacturers and suppliers, innovative production methods, sustainability commitments, and the industry’s critical role in green technology supply chains. It also examines market drivers, regulatory compliance, and supply chain strategies while answering common industry questions. The content is especially relevant for businesses seeking OEM solutions for aluminum profile treatment and battery production.

This comprehensive guide details the leading Nickel Sulfate Manufacturers and Suppliers in Germany, highlighting their strengths, product applications, and why Germany is a global leader. It covers selection criteria, market trends, and answers to key FAQs for buyers and industry professionals.

This article offers a comprehensive guide to the UK’s top Nickel Sulfate Manufacturers and Suppliers, highlighting industry applications, leading brands, and sourcing strategies in the rapidly growing British and global markets. From surface finishing to electric vehicle batteries, discover how to select the right partner and stay ahead of industry shifts.

This article explores the top Nickel Sulfate Manufacturers and Suppliers in America, highlighting their key products, application areas, and essentials of reliable sourcing. With detailed industry profiles, market trends, future outlooks, and FAQs, it serves as a vital comprehensive resource for businesses seeking high-quality nickel sulfate and dependable partnership.

Choosing the best chemical raw materials for aluminum profiles is **critical to ensuring strength, durability, corrosion resistance, and sustainability** in the final products. The selection impacts not only the mechanical and aesthetic qualities but also influences cost-effectiveness, production ef