Please Choose Your Language

Views: 222 Author: Carie Publish Time: 2025-03-12 Origin: Site

Content Menu

● Introduction to Sewage Treatment

● The Microbial Workforce in Sewage Treatment

>> Aerobic Bacteria: Oxygen-Dependent Degraders

>>> Key Species and Functions:

>> Anaerobic Bacteria: Methane Producers

>>> Key Species and Functions:

>> Facultative Bacteria: Adaptable All-Rounders

>> Protozoa and Metazoa: The Cleanup Crew

>> Fungi and Microalgae: Niche Players

● Advanced Microbial Technologies

>> 1. Microbial Fuel Cells (MFCs)

● Challenges in Microbial Sewage Treatment

● Environmental and Economic Impact

● FAQ

>> 1. How long do microbes take to treat sewage?

>> 2. Can sewage microbes harm human health?

>> 3. What happens to dead microbes in treated water?

>> 4. Do antibiotics in wastewater affect treatment microbes?

>> 5. How is microbial activity monitored in treatment plants?

Sewage treatment is a critical process that relies on microorganisms to break down organic matter and remove harmful substances from wastewater. This biological approach protects public health and ecosystems by reducing pollutants before water is discharged into the environment. Below, we explore the microbial workhorses behind sewage treatment, their mechanisms, and emerging innovations in the field.

Modern sewage treatment involves three stages:

1. Primary Treatment: Physical removal of large debris and suspended solids.

2. Secondary Treatment: Biological degradation of organic matter using microbes.

3. Tertiary Treatment: Advanced processes (e.g., filtration, disinfection) for polishing water quality.

The secondary treatment stage is where microorganisms shine, reducing biochemical oxygen demand (BOD) by up to 90% through metabolic activity.

Aerobic bacteria dominate activated sludge systems, where oxygen is pumped into wastewater to fuel their metabolism.

- Nitrosomonas & Nitrobacter: Convert toxic ammonia to nitrate via nitrification.

- Pseudomonas spp.: Degrade hydrocarbons and phenolic compounds.

- Zoogloea spp.: Form sticky bioflocs that trap organic particles.

Mechanism:

These bacteria oxidize organic carbon (C6H12O6 + 6O2 → 6CO2 + 6H2O) while generating energy.

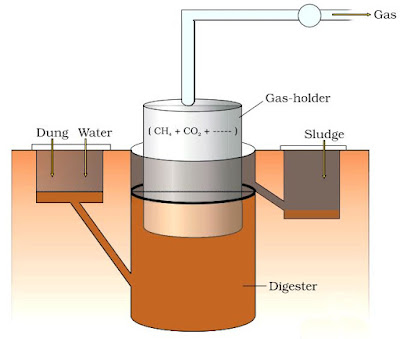

Operating in oxygen-free environments like anaerobic digesters, these microbes thrive in high-organic-load conditions.

- Methanogens: Archaea that produce methane (CH4) from CO2 and H2.

- Clostridium spp.: Break down complex polymers into fatty acids.

Process Stages:

1. Hydrolysis → 2. Acidogenesis → 3. Acetogenesis → 4. Methanogenesis

Output:

- Methane (used for energy generation)

- Reduced sludge volume (by 40–60%)

These versatile microbes switch between aerobic and anaerobic modes based on environmental conditions.

Examples:

- Escherichia coli: Breaks down lactose and proteins.

- Enterobacter spp.: Degrades petroleum hydrocarbons.

Advantage:

They stabilize systems during oxygen fluctuations, common in decentralized treatment plants.

Non-bacterial microbes enhance treatment efficiency:

| Organism | Role | Example Species |

|---|---|---|

| Ciliates | Consume free bacteria, clarify water | Vorticella, Paramecium |

| Rotifers | Graze on flocs, reduce sludge | Philodina |

| Nematodes | Break down fungal/bacterial biofilms | Caenorhabditis |

- Fungi (e.g., Aspergillus niger): Degrade lignin and pharmaceuticals.

- Microalgae (e.g., Chlorella): Absorb nitrogen/phosphorus while producing oxygen.

Case Study:

A plant in Singapore uses Chlorella vulgaris to remove 89% of nitrogen and 93% of phosphorus from sewage.

Bacteria like Geobacter sulfurreducens generate electricity while treating wastewater.

- Output: 0.5–1.2 kWh/m³ of treated water

- Applications: Remote sensors, low-energy treatment plants

Adding engineered strains (e.g., Dechloromonas aromatica for perchlorate removal) boosts treatment efficiency.

Self-immobilized microbial aggregates (1–3 mm diameter) withstand high loads.

- Benefits: 30% less energy use vs. conventional systems

- Temperature Sensitivity: Mesophilic microbes (30–40°C) underperform in cold climates.

- Toxicity: Heavy metals (e.g., Hg, Cd) inhibit microbial activity at >2 ppm.

- Foaming Issues: Filamentous bacteria like Microthrix parvicella disrupt sludge settling.

- CRISPR-Edited Microbes: Strains resistant to antibiotics and heavy metals.

- Biochar Amendments: Enhances microbial growth by 22% (University of Queensland, 2024).

Anaerobic digestion cuts CO2 emissions by 1.3 kg per m³ of treated sewage compared to aerobic methods.

| Process | Cost (USD/m³) | BOD Removal Efficiency |

|---|---|---|

| Activated Sludge | 0.15–0.30 | 85–95% |

| Anaerobic Digestion | 0.08–0.20 | 70–85% |

| MFC Systems | 0.40–0.60 | 60–75% |

Microorganisms form the backbone of sustainable sewage treatment, offering cost-effective and eco-friendly solutions. As genetic engineering and hybrid technologies evolve, microbial systems will play an even greater role in achieving global water security goals.

Most secondary treatment processes require 6–12 hours for BOD reduction, while anaerobic digestion spans 15–30 days.

Pathogens like *Salmonella* are eliminated during treatment via UV disinfection or chlorination.

They form part of the "waste sludge," which is dewatered and incinerated/land-applied as fertilizer.

Yes, high antibiotic concentrations (>1 mg/L) can inhibit bacterial activity. Advanced oxidation steps are often added.

Techniques include:

- ATP bioluminescence testing

- DNA sequencing (e.g., 16S rRNA analysis)

- Microscopic sludge index measurements

This article highlights the top stannous sulfate manufacturers and suppliers in the UK, focusing on their product quality, industrial applications, and market presence. It emphasizes the UK's strength in producing high-purity stannous sulfate for surface treatment, water treatment, and electroplating industries. Key players like REAXIS and Atotech lead the market with innovative solutions, while OEM support and regulatory compliance remain core advantages of UK suppliers. The article also addresses the compound's uses and includes a detailed FAQ to assist industry professionals.

Germany leads Europe in Stannous Sulfate manufacturing, supplying high-purity, reliable chemicals essential for electroplating, glass production, pharmaceuticals, and more. Key German suppliers like TIB Chemicals AG, MCC Menssing, Univar Solutions GmbH, and VMP Chemiekontor GmbH offer tailored solutions, strict quality control, and global distribution for diverse industrial demands.

This article explores the top stannous sulfate manufacturers and suppliers in Europe, highlighting leading companies like TIB Chemicals and Chimica Panzeri. It details production technologies, quality standards, industry applications, and OEM services, offering insights for markets requiring high-purity stannous sulfate chemicals.

This article explores the top stannous sulfate manufacturers and suppliers in France, highlighting their product quality, compliance with environmental standards, customized OEM services, and key industrial applications such as aluminum surface treatment, electronics, pharmaceuticals, and wastewater management.

This article explores the top stannous sulfate manufacturers and suppliers in America, detailing key companies, product forms, industries served, manufacturing processes, quality controls, and environmental considerations. It highlights the benefits of sourcing stannous sulfate locally with customization and technical support options. Insightful images illustrate stannous sulfate forms, production, and applications in industrial processes. Finally, a FAQ section addresses common queries related to stannous sulfate use and supply.

This comprehensive report explores Japan's top nickel sulfate manufacturers and suppliers, highlighting their production capabilities, market positions, and product applications. Featuring companies like Sumitomo Metal Mining and SEIDO Chemical Industry, the article delves into manufacturing processes, industry uses, and environmental practices, reflecting the pivotal role of Japanese firms in the advancing global nickel sulfate market.

South Korea is a leading global hub for nickel sulfate manufacturing, dominated by Korea Zinc and KEMCO with a combined annual capacity of 80,000 tons. Leveraging advanced smelting technologies and government-supported strategic status, these manufacturers supply high-quality nickel sulfate for electric vehicle batteries, surface treatment, and chemical industries. South Korean suppliers offer comprehensive OEM services to international clients, meeting growing global demand with innovation, sustainability, and quality.

This article provides a comprehensive overview of leading nickel sulfate manufacturers and suppliers in Portugal, covering their technological capabilities, product lines, market roles, and strict compliance with international standards. Highlighting diverse applications from electroplating to battery manufacturing, it showcases Portugal’s growing importance in the global nickel sulfate supply chain. Accompanied by relevant images, the article emphasizes sustainability, innovation, and quality as cornerstones of the Portuguese chemical sector.

This article explores the top nickel sulfate manufacturers and suppliers in Spain, highlighting their product offerings, quality standards, and strategic advantages. It covers Spanish industry applications, OEM services, and explains why Spain is a preferred sourcing hub for global chemical buyers. The article also includes detailed FAQs and relevant images to provide a comprehensive understanding of the nickel sulfate market in Spain.

Italy’s nickel sulfate manufacturing and supply chain is advanced, diverse, and globally integrated—supporting key industries like batteries, electroplating, and catalysts. With leading companies, customized services, and sustainable practices, Italian nickel sulfate manufacturers and suppliers are crucial to meeting the world’s growing demand for this essential chemical.

This article provides an in-depth overview of the top nickel sulfate manufacturers and suppliers in Russia, focusing on major companies like Norilsk Nickel, their production processes, market presence, environmental initiatives, and the diverse industrial applications of nickel sulfate. It serves as a valuable resource for international businesses looking to source high-quality nickel sulfate from Russia.

Aluminum alloys have become indispensable materials in modern industry, owing to their light weight, high strength-to-weight ratio, corrosion resistance, workability, and versatility. However, their durability—especially when used in challenging environments—is critically dependent on

Electrophoretic coatings, often referred to as *E-coatings* or *electrophoretic deposition (EPD)*, have revolutionized surface finishing in the modern manufacturing landscape. They blend chemistry, material science, and advanced technology to create coatings that are durable, uniform, and environmen

Discover Europe's most prominent Nickel Sulfate Manufacturers and Suppliers, including sustainability-focused innovators and rapid-response distributors serving the EV, electroplating, and advanced materials sectors. Learn about top companies, key trends, market drivers, and FAQs to inform your industrial chemical sourcing decisions. This comprehensive guide highlights the critical role nickel sulfate plays in Europe’s green industrial future.

This article details France’s leading role in nickel sulfate production, covering major manufacturers and suppliers, innovative production methods, sustainability commitments, and the industry’s critical role in green technology supply chains. It also examines market drivers, regulatory compliance, and supply chain strategies while answering common industry questions. The content is especially relevant for businesses seeking OEM solutions for aluminum profile treatment and battery production.

This comprehensive guide details the leading Nickel Sulfate Manufacturers and Suppliers in Germany, highlighting their strengths, product applications, and why Germany is a global leader. It covers selection criteria, market trends, and answers to key FAQs for buyers and industry professionals.

This article offers a comprehensive guide to the UK’s top Nickel Sulfate Manufacturers and Suppliers, highlighting industry applications, leading brands, and sourcing strategies in the rapidly growing British and global markets. From surface finishing to electric vehicle batteries, discover how to select the right partner and stay ahead of industry shifts.

This article explores the top Nickel Sulfate Manufacturers and Suppliers in America, highlighting their key products, application areas, and essentials of reliable sourcing. With detailed industry profiles, market trends, future outlooks, and FAQs, it serves as a vital comprehensive resource for businesses seeking high-quality nickel sulfate and dependable partnership.

Choosing the best chemical raw materials for aluminum profiles is **critical to ensuring strength, durability, corrosion resistance, and sustainability** in the final products. The selection impacts not only the mechanical and aesthetic qualities but also influences cost-effectiveness, production ef

In the global industrial landscape, **chemical raw materials for surface treatment** play a critically transformative role in enhancing the durability, functionality, and aesthetics of countless products. Surface treatment chemicals help prevent corrosion, improve adhesion, increase wear resistance,