Please Choose Your Language

Views: 222 Author: Carie Publish Time: 2025-02-21 Origin: Site

Content Menu

● The Shift Towards Decentralized Wastewater Treatment

>> Advantages of Decentralized Systems

>> Case Studies of Successful Decentralized Systems

● Innovative Technologies in Wastewater Treatment

● The Role of Technology in Wastewater Reuse

>> Advanced Oxidation Processes

● Transforming Waste into Resources

● Emerging Trends in Wastewater Solutions

>> 3. Public-Private Partnerships

● Challenges Facing Wastewater Solutions

● FAQ

>> 1. What are decentralized wastewater treatment systems?

>> 2. How do constructed wetlands work?

>> 3. What is nutrient recovery in wastewater treatment?

>> 4. Can wastewater treatment generate energy?

>> 5. What challenges do new wastewater technologies face?

Wastewater management has evolved significantly in recent years, driven by the need for sustainable practices, technological advancements, and increasing environmental concerns. Experts agree that innovative approaches are essential to address the challenges posed by traditional sewage treatment methods. This article explores current trends in wastewater solutions, focusing on decentralized systems, advanced technologies, and the transformation of waste into valuable resources.

Decentralization is emerging as a key trend in wastewater management. Traditional centralized systems often struggle to cope with urban growth and extreme weather events. Experts like Riccardo Zennaro from the United Nations Environment Programme (UNEP) advocate for smaller, localized systems that can be more adaptable and cost-effective. These decentralized systems can effectively treat wastewater at or near the point of generation, reducing the burden on large treatment plants and minimizing transportation costs associated with sewage disposal.

- Cost-Effectiveness: Smaller treatment facilities can be less expensive to build and maintain compared to large centralized plants.

- Flexibility: Decentralized systems can be tailored to meet specific local needs and can be scaled up or down as required.

- Environmental Benefits: By treating wastewater closer to its source, these systems reduce the risk of pollution from sewage overflows during heavy rains.

Several cities around the world have successfully implemented decentralized wastewater treatment systems. For instance, in Graham, North Carolina, a community-based system treats wastewater using a combination of constructed wetlands and aerobic treatment units. This system has not only improved water quality but also enhanced local ecosystems by providing habitats for wildlife.

In Singapore, the government has invested heavily in decentralized systems as part of its "Four National Taps" strategy for water sustainability. The use of small-scale treatment plants allows for efficient water reuse in landscaping and industrial applications, showcasing how urban areas can effectively manage their water resources.

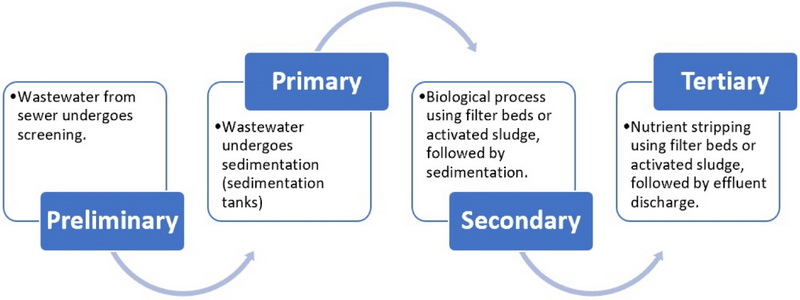

Recent advancements in technology are revolutionizing how wastewater is treated. Techniques such as constructed wetlands, membrane bioreactors, and algal biofilm systems are gaining traction for their efficiency and sustainability.

Constructed wetlands mimic natural wetlands to treat wastewater. They utilize plants and microorganisms to filter pollutants effectively. These systems are not only cost-effective but also enhance local biodiversity by creating habitats for various species.

A notable innovation is the use of algal biofilm systems, which leverage algae's ability to absorb nutrients like nitrogen and phosphorus from wastewater. This method not only purifies water but also produces biomass that can be harvested and sold as fertilizer.

The concept of water reuse is gaining momentum as a sustainable solution to water scarcity. Technologies that enable the recycling of treated wastewater for non-potable uses (such as irrigation and industrial processes) are being developed and implemented worldwide.

Technologies like advanced oxidation processes (AOPs) are particularly effective in treating non-biodegradable pollutants found in industrial wastewater. Companies like CleanInWater Inc. are pioneering these technologies, which allow for rapid removal of contaminants with minimal operational costs.

Membrane bioreactors (MBRs) combine biological treatment with membrane filtration, resulting in high-quality effluent suitable for reuse. MBRs are increasingly being adopted in urban areas where space is limited, providing an efficient solution for treating municipal wastewater.

Experts emphasize the importance of viewing wastewater not just as waste but as a potential resource. The transformation of sewage into valuable materials is a central theme in modern wastewater management.

Many treatment processes now focus on recovering nutrients from wastewater. For example, phosphorus recovery techniques can convert waste into fertilizers, thereby closing the nutrient loop and reducing reliance on synthetic fertilizers.

Wastewater treatment processes can also be designed to generate energy. Anaerobic digestion, for instance, produces biogas that can be harnessed for electricity or heating purposes, contributing to a circular economy approach in urban water management.

As we look toward the future, several emerging trends are shaping the landscape of wastewater management:

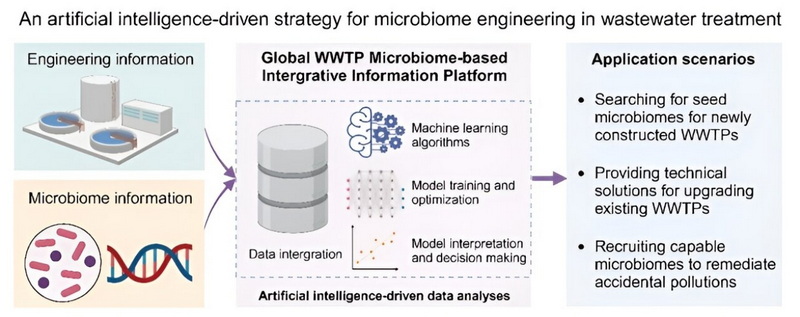

The integration of smart technologies into wastewater management is becoming increasingly prevalent. Sensors and IoT devices enable real-time monitoring of water quality and flow rates, allowing operators to optimize treatment processes and respond quickly to issues such as leaks or contamination events.

Green infrastructure solutions—such as green roofs, permeable pavements, and bioswales—are being integrated into urban planning to manage stormwater runoff effectively. These approaches not only reduce pressure on sewage systems but also improve urban aesthetics and biodiversity.

Collaborations between public entities and private companies are becoming more common in developing innovative wastewater solutions. These partnerships leverage private sector expertise and investment to enhance public infrastructure projects.

Despite advancements, several challenges remain in implementing innovative wastewater solutions:

- Funding and Investment: Many municipalities lack the financial resources needed to invest in new technologies or decentralized systems.

- Regulatory Barriers: Existing regulations may not accommodate new treatment methods or water reuse strategies.

- Public Acceptance: Community buy-in is crucial for the success of decentralized systems; public education about their benefits is essential.

The landscape of wastewater management is rapidly changing due to innovative technologies and a shift towards decentralized systems. By transforming waste into valuable resources and promoting sustainable practices, experts believe we can create more resilient urban environments capable of addressing future water challenges.

Decentralized systems treat wastewater at or near its source rather than transporting it to a centralized facility. This approach offers greater flexibility and cost-effectiveness.

Constructed wetlands use natural processes involving plants and microorganisms to filter pollutants from wastewater, mimicking the functions of natural wetlands.

Nutrient recovery involves extracting valuable nutrients like nitrogen and phosphorus from treated wastewater, which can then be used as fertilizers.

Yes, certain processes like anaerobic digestion produce biogas that can be used for electricity generation or heating, contributing to energy sustainability.

Challenges include funding limitations, regulatory barriers, and the need for public acceptance of new treatment methods.

This article highlights the top stannous sulfate manufacturers and suppliers in the UK, focusing on their product quality, industrial applications, and market presence. It emphasizes the UK's strength in producing high-purity stannous sulfate for surface treatment, water treatment, and electroplating industries. Key players like REAXIS and Atotech lead the market with innovative solutions, while OEM support and regulatory compliance remain core advantages of UK suppliers. The article also addresses the compound's uses and includes a detailed FAQ to assist industry professionals.

This article explores the top stannous sulfate manufacturers and suppliers in Europe, highlighting leading companies like TIB Chemicals and Chimica Panzeri. It details production technologies, quality standards, industry applications, and OEM services, offering insights for markets requiring high-purity stannous sulfate chemicals.

This article explores the top stannous sulfate manufacturers and suppliers in France, highlighting their product quality, compliance with environmental standards, customized OEM services, and key industrial applications such as aluminum surface treatment, electronics, pharmaceuticals, and wastewater management.

This article explores the top stannous sulfate manufacturers and suppliers in America, detailing key companies, product forms, industries served, manufacturing processes, quality controls, and environmental considerations. It highlights the benefits of sourcing stannous sulfate locally with customization and technical support options. Insightful images illustrate stannous sulfate forms, production, and applications in industrial processes. Finally, a FAQ section addresses common queries related to stannous sulfate use and supply.

This comprehensive report explores Japan's top nickel sulfate manufacturers and suppliers, highlighting their production capabilities, market positions, and product applications. Featuring companies like Sumitomo Metal Mining and SEIDO Chemical Industry, the article delves into manufacturing processes, industry uses, and environmental practices, reflecting the pivotal role of Japanese firms in the advancing global nickel sulfate market.

South Korea is a leading global hub for nickel sulfate manufacturing, dominated by Korea Zinc and KEMCO with a combined annual capacity of 80,000 tons. Leveraging advanced smelting technologies and government-supported strategic status, these manufacturers supply high-quality nickel sulfate for electric vehicle batteries, surface treatment, and chemical industries. South Korean suppliers offer comprehensive OEM services to international clients, meeting growing global demand with innovation, sustainability, and quality.

This article provides a comprehensive overview of leading nickel sulfate manufacturers and suppliers in Portugal, covering their technological capabilities, product lines, market roles, and strict compliance with international standards. Highlighting diverse applications from electroplating to battery manufacturing, it showcases Portugal’s growing importance in the global nickel sulfate supply chain. Accompanied by relevant images, the article emphasizes sustainability, innovation, and quality as cornerstones of the Portuguese chemical sector.

This article explores the top nickel sulfate manufacturers and suppliers in Spain, highlighting their product offerings, quality standards, and strategic advantages. It covers Spanish industry applications, OEM services, and explains why Spain is a preferred sourcing hub for global chemical buyers. The article also includes detailed FAQs and relevant images to provide a comprehensive understanding of the nickel sulfate market in Spain.

Italy’s nickel sulfate manufacturing and supply chain is advanced, diverse, and globally integrated—supporting key industries like batteries, electroplating, and catalysts. With leading companies, customized services, and sustainable practices, Italian nickel sulfate manufacturers and suppliers are crucial to meeting the world’s growing demand for this essential chemical.

This article provides an in-depth overview of the top nickel sulfate manufacturers and suppliers in Russia, focusing on major companies like Norilsk Nickel, their production processes, market presence, environmental initiatives, and the diverse industrial applications of nickel sulfate. It serves as a valuable resource for international businesses looking to source high-quality nickel sulfate from Russia.

Aluminum alloys have become indispensable materials in modern industry, owing to their light weight, high strength-to-weight ratio, corrosion resistance, workability, and versatility. However, their durability—especially when used in challenging environments—is critically dependent on

Electrophoretic coatings, often referred to as *E-coatings* or *electrophoretic deposition (EPD)*, have revolutionized surface finishing in the modern manufacturing landscape. They blend chemistry, material science, and advanced technology to create coatings that are durable, uniform, and environmen

Discover Europe's most prominent Nickel Sulfate Manufacturers and Suppliers, including sustainability-focused innovators and rapid-response distributors serving the EV, electroplating, and advanced materials sectors. Learn about top companies, key trends, market drivers, and FAQs to inform your industrial chemical sourcing decisions. This comprehensive guide highlights the critical role nickel sulfate plays in Europe’s green industrial future.

This article details France’s leading role in nickel sulfate production, covering major manufacturers and suppliers, innovative production methods, sustainability commitments, and the industry’s critical role in green technology supply chains. It also examines market drivers, regulatory compliance, and supply chain strategies while answering common industry questions. The content is especially relevant for businesses seeking OEM solutions for aluminum profile treatment and battery production.

This comprehensive guide details the leading Nickel Sulfate Manufacturers and Suppliers in Germany, highlighting their strengths, product applications, and why Germany is a global leader. It covers selection criteria, market trends, and answers to key FAQs for buyers and industry professionals.

This article offers a comprehensive guide to the UK’s top Nickel Sulfate Manufacturers and Suppliers, highlighting industry applications, leading brands, and sourcing strategies in the rapidly growing British and global markets. From surface finishing to electric vehicle batteries, discover how to select the right partner and stay ahead of industry shifts.

This article explores the top Nickel Sulfate Manufacturers and Suppliers in America, highlighting their key products, application areas, and essentials of reliable sourcing. With detailed industry profiles, market trends, future outlooks, and FAQs, it serves as a vital comprehensive resource for businesses seeking high-quality nickel sulfate and dependable partnership.

Choosing the best chemical raw materials for aluminum profiles is **critical to ensuring strength, durability, corrosion resistance, and sustainability** in the final products. The selection impacts not only the mechanical and aesthetic qualities but also influences cost-effectiveness, production ef

In the global industrial landscape, **chemical raw materials for surface treatment** play a critically transformative role in enhancing the durability, functionality, and aesthetics of countless products. Surface treatment chemicals help prevent corrosion, improve adhesion, increase wear resistance,

Aluminum stands out in the materials world due to its combination of light weight, high strength-to-weight ratio, and natural corrosion resistance. Yet, despite its excellent surface passivation, aluminum's vulnerability in aggressive environments, such as marine or industrial atmospheres, necessita