Please Choose Your Language

Views: 222 Author: Carie Publish Time: 2025-03-13 Origin: Site

Content Menu

● Introduction to Sewage Treatment Plants

>> Importance of Sewage Treatment

● Technologies Used in Sewage Treatment

● Benefits of Sewage Treatment Plants

● Challenges and Future Directions

● Case Studies: Successful Sewage Treatment Initiatives

● FAQ

>> 1. What is the primary function of a sewage treatment plant?

>> 2. What are the main stages of sewage treatment?

>> 3. What technologies are used in secondary treatment?

>> 4. What are the benefits of sewage treatment plants?

>> 5. What challenges do sewage treatment plants face?

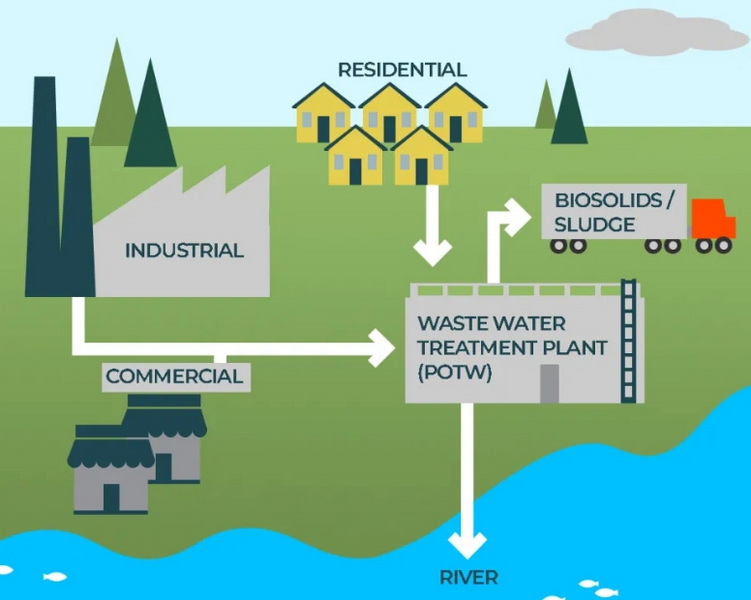

Sewage treatment plants are crucial facilities designed to remove contaminants from wastewater, ensuring that the water released back into the environment is safe and does not harm ecosystems. These plants employ a combination of physical, chemical, and biological processes to achieve this goal. In this article, we will delve into the workings of a sewage treatment plant, exploring its components, technologies, and benefits.

Sewage treatment plants are essential for maintaining public health and environmental safety. They handle wastewater from residential, commercial, and industrial sources, treating it to remove pollutants before discharge into water bodies or reuse for non-potable purposes like irrigation.

Without proper treatment, sewage can lead to severe environmental and health issues. Untreated wastewater can contaminate water sources, harm aquatic life, and spread diseases. Therefore, sewage treatment plants play a vital role in protecting ecosystems and human health.

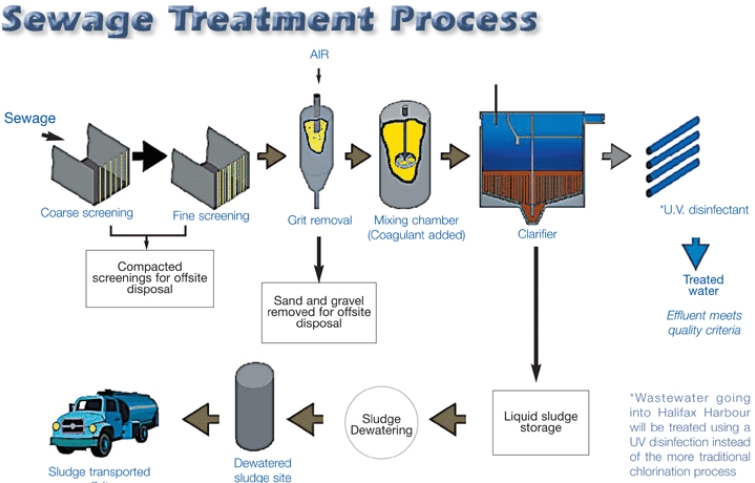

The treatment process typically involves three main stages: primary, secondary, and tertiary treatment. Each stage is crucial for removing different types of contaminants.

Primary treatment involves the physical removal of large contaminants and suspended solids from the wastewater. This stage includes processes such as screening and grit removal.

- Screen Chamber & Oil/Grease Trap: These components filter out plastics, paper, and floating oils to prevent blockages in downstream equipment.

- Equalization Tank: This tank collects and aerates wastewater to balance flow rates and prevent sudden changes that could disrupt the treatment process.

- Primary Clarifier: Also known as a sedimentation tank, it allows heavier solids to settle at the bottom while lighter materials float to the top.

Secondary treatment focuses on breaking down organic matter using biological processes. Various technologies are employed during this stage:

- Activated Sludge Process (ASP): Microorganisms in an aeration tank break down organic pollutants with continuous aeration.

- Moving Bed Biofilm Reactor (MBBR): Floating bio-media support bacterial growth, reducing contaminants efficiently.

- Submerged Aerobic Fixed Film Reactor (SAFF): Combines fixed bio-media with aeration for energy-efficient organic pollutant breakdown.

- Sequencing Batch Reactor (SBR): Treats wastewater in batches, ideal for fluctuating loads.

- Membrane Bioreactor (MBR): Integrates biological treatment with membrane filtration for high-quality effluent suitable for reuse.

Tertiary treatment, also known as advanced treatment, further polishes the water by removing remaining contaminants. This stage often includes processes like granular media filtration or disinfection to ensure the water meets stringent quality standards for discharge or reuse.

- Disinfection: Uses chlorine, ozone, or UV light to kill bacteria and viruses.

- Filtration: Removes remaining suspended solids, improving water clarity.

Sewage treatment plants utilize a variety of technologies to enhance efficiency and effectiveness:

- Biological Treatment: Uses microorganisms to break down organic pollutants.

- Chemical Treatment: Involves the addition of chemicals to remove specific contaminants.

- Filtration Systems: Such as membrane bioreactors for high-quality effluent.

- Advanced Oxidation Processes (AOPs): Utilize oxidizing agents to degrade persistent pollutants.

The benefits of these plants are multifaceted:

- Environmental Protection: Prevents pollution of water bodies and protects aquatic life.

- Public Health: Reduces the risk of waterborne diseases.

- Water Reuse: Treated water can be reused for irrigation, toilet flushing, and other non-potable purposes.

- Economic Benefits: Supports agriculture and industry by providing a reliable water source.

Despite their importance, sewage treatment plants face challenges such as aging infrastructure and increasing wastewater volumes. Future directions include adopting more efficient technologies and integrating renewable energy sources to reduce operational costs and environmental impact.

- Sustainable Energy Integration: Incorporating solar or wind power to reduce energy dependence.

- Advanced Materials: Using innovative materials for more efficient filtration and treatment processes.

- Digitalization: Implementing smart technologies for real-time monitoring and optimization of treatment processes.

Several countries have implemented successful sewage treatment initiatives:

- Singapore: Known for its efficient water management system, Singapore reuses treated water extensively.

- Sweden: Focuses on sustainable technologies and energy efficiency in sewage treatment.

- Australia: Implements advanced membrane technologies for high-quality effluent.

Sewage treatment plants are vital for maintaining environmental health and public safety. By understanding the processes and technologies involved, we can appreciate the complexity and importance of these facilities. As technology advances, sewage treatment will become more efficient and sustainable, ensuring cleaner water for future generations.

A sewage treatment plant's primary function is to remove contaminants from wastewater, making it safe for discharge into the environment or reuse.

The main stages are primary treatment (physical removal of solids), secondary treatment (biological breakdown of organic matter), and tertiary treatment (advanced polishing).

Technologies include the Activated Sludge Process, Moving Bed Biofilm Reactor, Submerged Aerobic Fixed Film Reactor, Sequencing Batch Reactor, and Membrane Bioreactor.

Benefits include environmental protection, public health safety, and water reuse opportunities.

Challenges include aging infrastructure, increasing wastewater volumes, and the need for more efficient and sustainable technologies.

Aluminum alloys have become indispensable materials in modern industry, owing to their light weight, high strength-to-weight ratio, corrosion resistance, workability, and versatility. However, their durability—especially when used in challenging environments—is critically dependent on

Electrophoretic coatings, often referred to as *E-coatings* or *electrophoretic deposition (EPD)*, have revolutionized surface finishing in the modern manufacturing landscape. They blend chemistry, material science, and advanced technology to create coatings that are durable, uniform, and environmen

Discover Europe's most prominent Nickel Sulfate Manufacturers and Suppliers, including sustainability-focused innovators and rapid-response distributors serving the EV, electroplating, and advanced materials sectors. Learn about top companies, key trends, market drivers, and FAQs to inform your industrial chemical sourcing decisions. This comprehensive guide highlights the critical role nickel sulfate plays in Europe’s green industrial future.

This article details France’s leading role in nickel sulfate production, covering major manufacturers and suppliers, innovative production methods, sustainability commitments, and the industry’s critical role in green technology supply chains. It also examines market drivers, regulatory compliance, and supply chain strategies while answering common industry questions. The content is especially relevant for businesses seeking OEM solutions for aluminum profile treatment and battery production.

This comprehensive guide details the leading Nickel Sulfate Manufacturers and Suppliers in Germany, highlighting their strengths, product applications, and why Germany is a global leader. It covers selection criteria, market trends, and answers to key FAQs for buyers and industry professionals.

This article offers a comprehensive guide to the UK’s top Nickel Sulfate Manufacturers and Suppliers, highlighting industry applications, leading brands, and sourcing strategies in the rapidly growing British and global markets. From surface finishing to electric vehicle batteries, discover how to select the right partner and stay ahead of industry shifts.

This article explores the top Nickel Sulfate Manufacturers and Suppliers in America, highlighting their key products, application areas, and essentials of reliable sourcing. With detailed industry profiles, market trends, future outlooks, and FAQs, it serves as a vital comprehensive resource for businesses seeking high-quality nickel sulfate and dependable partnership.

Choosing the best chemical raw materials for aluminum profiles is **critical to ensuring strength, durability, corrosion resistance, and sustainability** in the final products. The selection impacts not only the mechanical and aesthetic qualities but also influences cost-effectiveness, production ef

In the global industrial landscape, **chemical raw materials for surface treatment** play a critically transformative role in enhancing the durability, functionality, and aesthetics of countless products. Surface treatment chemicals help prevent corrosion, improve adhesion, increase wear resistance,

Aluminum stands out in the materials world due to its combination of light weight, high strength-to-weight ratio, and natural corrosion resistance. Yet, despite its excellent surface passivation, aluminum's vulnerability in aggressive environments, such as marine or industrial atmospheres, necessita

Aluminum alloys have revolutionized modern engineering, offering unmatched versatility, lightness, and strength. But the secret to their remarkable properties lies in the careful selection and combination of raw materials. This comprehensive guide explores the best chemical raw materials for aluminu

Aluminum is a cornerstone of modern manufacturing, renowned for its exceptional strength-to-weight ratio, corrosion resistance, and versatility. However, to realize its full potential in diverse industrial applications, **surface treatment** is essential. Surface treatments enhance al

In modern chemistry and materials engineering, chemical raw materials and electrophoretic materials play crucial but distinct roles. While chemical raw materials refer broadly to the fundamental substances used to create chemicals, polymers, coatings, and various compounds, el

Metal treatment is a foundational process in countless industries, from automotive to aerospace, construction, electronics, and consumer goods. The selection of the right chemical raw materials is paramount; it determines not only the quality, performance, and longevity of the finished product but a

Aluminum profiles are fundamental components across modern industries—from construction and transportation to electronics and advanced manufacturing. The secret to their performance, longevity, and aesthetics lies not just in mec

Incomplete neutralization and descaling of aluminum profiles may be caused by the following factors:1. Process Parameter Issues: Such as insufficient treatment time, inappropriate temperature, or inaccurate solution concentration. If the treatment time is too short, the neutralization and descaling

After aluminum alloy undergoes anodizing treatment, an oxide film is formed that is resistant to oxidation, rust, corrosion, and wear. Furthermore, this oxide film is extremely stable in natural ecological environments, effectively protecting the surface of aluminum alloy products. The outer layer o

This article provides a comprehensive overview of the top sodium hydroxide manufacturers and suppliers in the UK, highlighting their products, specializations, and service features for various industries. It is designed to guide OEMs, resellers, and end-users in making informed choices and ensuring consistent access to high-quality sodium hydroxide. Covering market trends, safety, packaging, and FAQs, the article is an essential resource for anyone in need of sodium hydroxide in the UK market.

This article provides an in-depth overview of the top sodium hydroxide manufacturers and suppliers in Japan. It highlights key companies such as Tosoh Corporation, Shin-Etsu Chemical, Tokuyama Corporation, Sumitomo Chemical, and Kureha Corporation, detailing their production facilities, technologies, and industrial applications. The article also covers the importance of OEM services, environmental initiatives, and future industry trends, offering valuable insights for global businesses seeking reliable chemical partners.

This article provides an in-depth look at the top sodium hydroxide manufacturers and suppliers in South Korea. It covers their product types, industrial applications, technological strengths, quality certifications, environmental practices, and supply chain capabilities. Leading companies like OCI and YOUNG JIN CHEMICAL are highlighted for their innovation and reliability in supplying high-purity caustic soda to global markets.